Fretting Corrosion is a type of friction damage. It’s caused by a lack of lubrication or improper maintenance. Fretting Corrosion can happen in a few places and cause different issues. The cause depends upon where it occurred. The correct steps to avoid Corrosion issues are mainly in the 10,000,000-stitch maintenance. To check if you need to perform the maintenance and to see the steps, open your Operating Software and go to Tools > Settings > Timers. Click the Step button to the right of the maintenance you would like to do.

If you notice Fretting Corrosion, you might not notice any performance of sew quality issues. If you are not noticing any other problems, you can ignore the Corrosion and use the machine normally. The Corrosion might become worse over time, especially if the maintenances are not performed correctly.

If you notice movement issues due to the Corrosion, the effected part will need to be replaced.

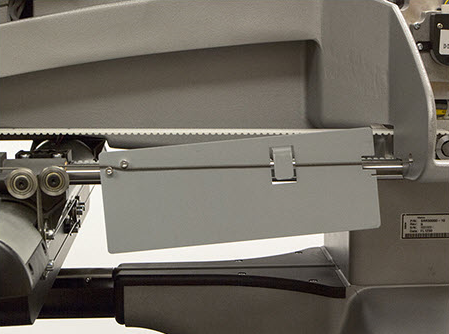

- If the Corrosion is inside the x-beam along the rails, it might cause binding in the x-axis, jumpy/uneven movement of the x-carriage, or excess noise when the carriage moves. This Corrosion might be caused by not performing the x-beam rail maintenance

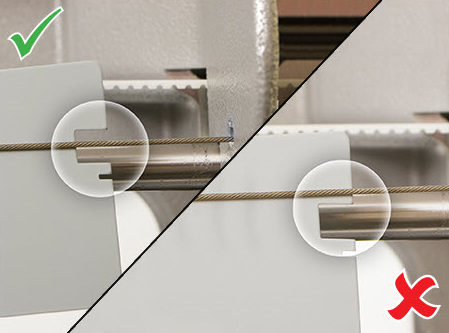

It can also be caused by improper x-cable maintenance. The cable can be adjusted under both the left and right Upper Side Arm Covers. If both sides are maxed out and cannot be adjusted further you might need a new X-cable.

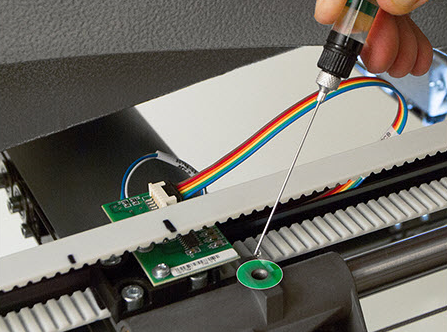

If the Corrosion is on the y-rails it might cause binding in the y-axis, jumpy/uneven movement of the x-beam, or excess noise when the x-beam moves. This Corrosion might be caused by not performing the y-rail maintenance correctly, this maintenance should be done with the Needle Nose Pen Oiler.