Review this video on the correct Thread Path.

If you are running into an issue that is Needle Specific, for example your 4th needle sews fine but your 9th is Thread Breaking, you might have a problem along your Thread Path. Follow the steps below.

1. Make sure you are using the correct type of Thread Stabilizer / Holder. This can depend on the machine model and Thread Cone type.

2. Make sure the Thread Cones are fully seated against the thread tree base or holder. If not, the thread could become entangled beneath the cone.

3. The Thread Tubes should extend ½ - 1inch above the end of the cone. If the tube is not extended far enough, the thread might catch along the top of the cone. If the tube extends too far past the cone, the thread might wrap around and catch on the tube.

4. The Thread Tubes should be connected to the back of the Needle Case.

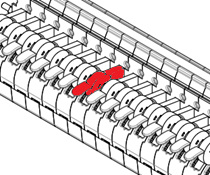

5. Make sure that thread is not caught or wrapped around the Thread Feeder gears.

6. Lift the Pinch Roller and gently pull some thread out, make sure it feels smooth

7. Make sure the Pinch Rollers are down.

8. Threads should be centered in the Groove of the Thread Feeder Front Cover P/N 32975:

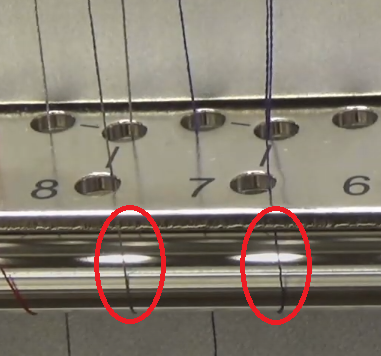

9. Make sure the thread follows the Correct Thread Path.

10. If the thread is not going around the Thread Sensor properly you can receive False Thread Breaks.

11. Before threading the needle, gently pull more thread out to make sure the path still feels smooth. If it does not, check for burrs. Rough edges, for example along the metal of the guide holes, can cause the thread to catch or break.