The Slim Line Clamping System is a spring loaded clamping device with interchangeable windows. Follow these instructions to install and use the Slim Line Clamping System. There are 4 sections below:

- Choosing the Correct Size of Slim Line Clamping System

- Connecting the Clamping System

- Adjusting the Clamping System

- Using the Clamping Windows

IMPORTANT: DO NOT WALK AWAY FROM THE MACHINE WITH THE CLAMP LEVER IN THE OPEN POSITION. THAT HAS BEEN KNOWN TO CAUSE DAMAGE TO THE MACHINE WHEN IT IS RESTARTED.

Choosing the Correct Size of Slim Line Chassis and Window Style

The Slim Line Clamping System is available in either Small or Large chassis.

- Small Slim Line 1 (chassis) PN: 17124 features different styles and sizes of clamping windows:

Stainless Steel (left) and Heavy Duty (right) Clamping Windows

- The Stainless Steel clamping windows are used for lightweight/thin fabrics.

- The Heavy Duty (painted yellow) clamping windows are for heavy fabrics that do not bend. Only one clamping window can be used at a time with the Slim Line adapter.

- See this article for the Slim Line 1 Hat Side Left and Right Windows.

- Large Slim Line 2 (chassis) PN: 33306 only has one style of clamping window, in various sizes.

Connecting the Clamping System

Start by choosing the Slim Line hoop and Centering the hoop within the software. Next, put the grabber bar down and power the Melco machine OFF. IMPORTANT: MAKE SURE YOUR MELCO MACHINE IS POWERED OFF BEFORE PROCEEDING.

Loosen and remove the four (4) mounting bracket screws and the hoop arms from the Melco X-Carriage (Illustration #1). You will only need two (2) of the screws for attaching your Slim Line hooping system.

Illustration #1

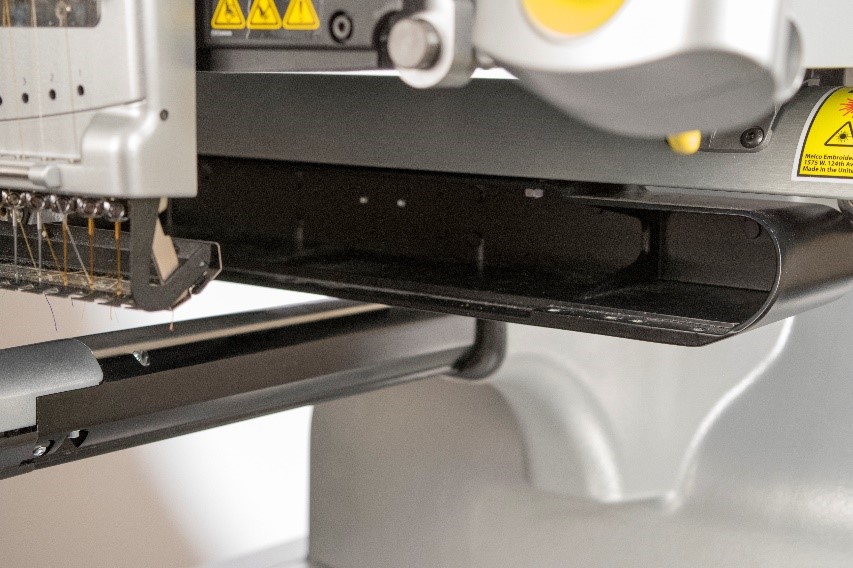

Push the Melco X-Carriage all the way to the back of the machine (Illustration #2).

Illustration #2

Place the red Slim Line hoop adapter on the Melco X-Carriage so that the holes in the adapter line up with the threaded holes in the X-Carriage. Make sure that the front of the Slim Line carriage is not beyond the front of the bobbin area on the front of the Melco machine (Illustration #3).

Illustration #3

Use two of the screws from your Melco machine (one on each side) to secure the Slim Line hoop adapter to the X-Carriage. Tighten the screws, but take caution not to over-tighten (Illustration #4).

Illustration #4

Adjusting the Clamping System

This adjustment is recommended when the clamping system is first installed. It shouldn't require additional adjustment unless problems start to occur over time.

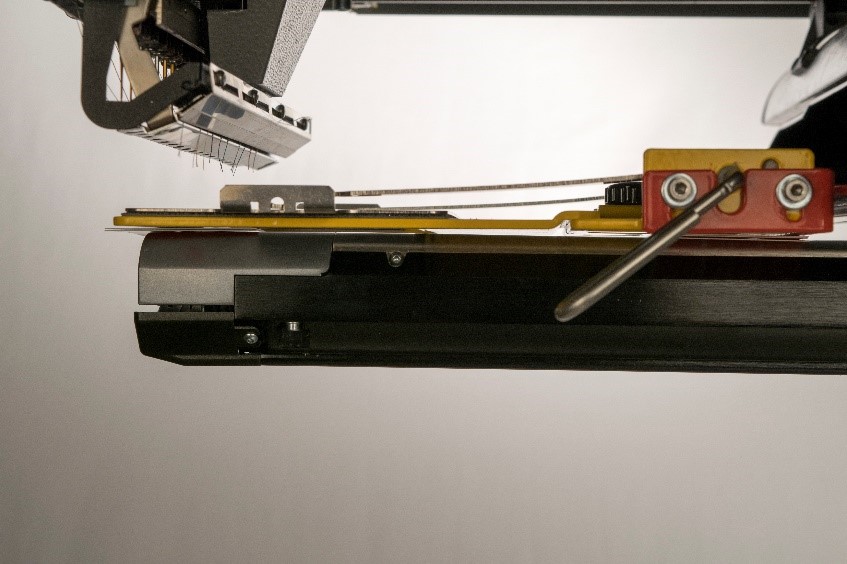

Use an Allen Wrench to loosen the Slim Line frame on the side of the frame, so that the base will move freely, up and down, in the mounting brackets.

Illustration #5

Place three (3) stacked business cards between the adapter towards the back of the cylinder arm, and place two (2) stacked business cards at the front of the cylinder arm. This achieves the proper height on the adapter and reduces wear on your Melco machine and the adapter, and sets the proper height for support by the cylinder arm. Use the four (4) side screws on the side of the red adapter to adjust the height of the frame. Tighten those screws firmly, but do not over-tighten.

Illustration #6

Before removing the business cards, with the clamp in the open position, push straight down onto the black knob that holds the lower window to confirm the proper clearance between the frame and the machine. This will locate the clamp base above the top of the sewing arm and set the proper height for support above the cylinder arm. Put the clamp in the closed position (Illustration #7).

IMPORTANT: DO NOT WALK AWAY FROM THE MACHINE WITH THE CLAMP LEVER IN THE OPEN POSITION. THAT HAS BEEN KNOWN TO CAUSE DAMAGE TO THE MACHINE WHEN IT IS RESTARTED.

Illustration #7

Check the alignment by looking (from side to side) at how the clamp is sitting above the cylinder arm. The base portion of the clamp should NOT be making contact with the cylinder arm under the black knob, and the front edge of the window should be even with, or slightly higher than the top of the throat plate (approx... 1/16” – ¼”). If bouncing or “flagging” occurs during sewing, readjust the clamp height. Retighten the screws, but do not over-tighten.

Using the Clamping Windows

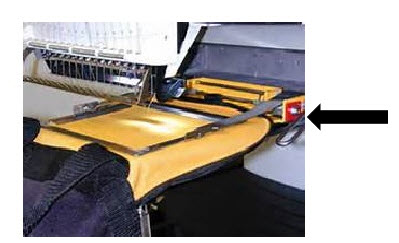

With the adjusted Slim Line Chassis attached to your Melco machine, attach the appropriate clamping window to the ends of the Chassis' spring steel clamping arms. The clamping arms will flex toward one another to allow the holding tabs to engage and/or disengage the notches in the upper window flanges (Illustration #8).

Illustration #8

The clamp opens and closes by activating the “U” shaped lever on the right side of the clamp body (Illustration #9). Rotating the lever UP releases and lifts the upper clamping window, making room for a garment or fabric to be embroidered. Rotating the lever DOWN lowers and locks the top window on the garment or item (Illustration #10). The lever arm should be rotated down only as far as necessary to clamp and lock the fabric. Pushing the lever arm too far down could damage or break the lever.

REMINDER: DO NOT WALK AWAY FROM THE MACHINE WITH THE CLAMP LEVER IN THE OPEN POSITION. THAT HAS BEEN KNOWN TO CAUSE DAMAGE TO THE MACHINE WHEN IT IS RESTARTED.

Illustration #9

Illustration #10

For instructions on centering the window on the Melco machine, see page 63 in the Melco OS manual.