Digitizing and Embroidering Help for Leather

General Tips:

- Some types of leather will not embroider properly even if the needle selected is correct. This is due to the tanning process that the leather has gone through. Certain tanning methods make needle eyes clog up with small leather pieces which causes constant thread breaks. The only way to tell if a certain leather type will embroider acceptably is to try it.

Digitizing Tips:

- Underlay should be kept to a minimum. Leather is very stable so there is not much need for it. The more stitches that are left out of the design, the better the embroidery will turn out.

- Stitch density should be reduced due to the possibility of the needle penetrations perforating (cutting out) the embroidery.

Embroidering Tips:

1. Use a 70 sharp needle for embroidery on leather. We find that the wedge point needle that is normally recommended for leather can damage the embroidery stitches during the sewing process. Sewing leather can create excess friction due to its thickness. Titanium nitride coated needles help alleviate much of the heat that is generated.

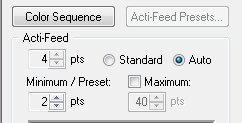

2. It is necessary to increase the thread feed on the Amaya when sewing leather. If this is not done the needle will get blunted (a mushroomed point) quickly due to the excessive thread tension which causes the needle to deflect into the hook basket metal. To increase the thread feed minimum, simply enter a larger number in the Minimum/Preset parameter. Increasing this number from the default 2 pts. to 6 pts. would be a good starting point.

Advanced View in MOS

Simplified View in MOS

3. Tear away backing would be the only backing necessary for leather. Many types of leather do not require any backing at all.